I-Flocculantidla ngokubizwa ngokuba yi "industrial panacea", enoluhlu olubanzi lwezicelo.Njengendlela yokomeleza ukwahlula okuqinileyo-olwelo kwintsimi yonyango lwamanzi, ingasetyenziselwa ukomeleza imvula ephambili yogutyulo, ukunyangwa kwe-flotation kunye nemvula yesibini emva kokusebenza kwendlela yodaka.Isenokusetyenziswa kunyango lwenqanaba lesithathu okanye unyango oluphezulu lwelindle.Kunyango lwamanzi, kukho izinto ezininzi ezichaphazela i-coagulation effect (idosi yeekhemikhali), ezi zinto zinzima ngakumbi, kubandakanywa ubushushu bamanzi, ixabiso le-pH kunye ne-alkalinity, ubume kunye nokugxininiswa kokungcola emanzini, iimeko zangaphandle zokugcinwa kwamanzi, njl. .

1. Impembelelo yobushushu bamanzi

Ubushushu bamanzi bunempembelelo enkulu ekusebenziseni iziyobisi, kunye nobushushu obuphantsi bamanzi ebusika

kunempembelelo enkulu ekusetyenzisweni kweziyobisi, nto leyo edla ngokukhokelela ekwakhekeni okucothayo kweeflocs ezinamasuntswana acolekileyo nakhululekileyo.Ezona zizathu ziphambili zezi:

I-hydrolysis ye-coagulants yetyuwa ye-inorganic i-endothermic reaction, kwaye i-hydrolysis ye-coagulants yamanzi ebushushu obuphantsi kunzima.

I-viscosity yamanzi anobushushu obuphantsi mkhulu, eyenza buthathaka intshukumo yeBrownian yamasuntswana okungcola

amanzi kunye nokunciphisa ithuba lokungqubana, elingenakulungelelaniswa nokutshatyalaliswa kunye nokuhlanganiswa kwee-colloids kwaye kuchaphazela ukukhula kweeflocs.

Xa ubushushu bamanzi buphantsi, i-hydration ye-colloidal particles iphuculwe, ethintela ukudibanisa kweengqungquthela ze-colloidal, kwaye iphinda ichaphazele amandla okubambelela phakathi kweengqungquthela ze-colloidal.

Ubushushu bamanzi bunxulumene ne-pH yamanzi.Xa ubushushu bamanzi buphantsi, ixabiso le-pH yamanzi liyanyuka, kwaye ixabiso le-pH elihambelanayo le-coagulation liya kwanda.Ke ngoko, ebusika kwimimandla ebandayo, kunzima ukufumana isiphumo esihle se-coagulation nokuba kufakwe inani elikhulu le-coagulant.

2. pH kunye ne-Alkalinity

Ixabiso le-pH liyisalathisi sokuba amanzi ane-acidic okanye i-alkaline, oko kukuthi, isalathisi sokugxilwa kwe-H + emanzini.Ixabiso le-pH lamanzi akrwada lichaphazela ngokuthe ngqo ukuphendula kwe-hydrolysis ye-coagulant, oko kukuthi, xa ixabiso le-pH lamanzi akrwada liphakathi koluhlu oluthile, umphumo we-coagulation unokuqinisekiswa.

Xa i-coagulant yongezwa emanzini, i-H + yoxinzelelo emanzini iyanda ngenxa ye-hydrolysis ye-coagulant, ebangela ukuba ixabiso le-pH lamanzi lihle kwaye lithintele i-hydrolysis.Ukugcina i-pH kuluhlu olufanelekileyo, amanzi kufuneka abe nezinto ezaneleyo ze-alkaline ukuthoba i-H+.Amanzi endalo aqulethe iqondo elithile le-alkalinity (ngokuqhelekileyo i-HCO3-), enokunciphisa i-H + eveliswa ngexesha le-hydrolysis ye-coagulant, kwaye ibe nefuthe le-buffering kwixabiso le-pH.Xa i-alkalinity yamanzi akrwada ayanelanga okanye i-coagulant yongezwa kakhulu, ixabiso le-pH lamanzi liya kuhla kakhulu, litshabalalise umphumo we-coagulation.

3. Impembelelo yobume kunye nokuxinwa kokungcola emanzini

Ubungakanani beqhekeza kunye nokuhlawulwa kwe-SS emanzini kuya kuchaphazela umphumo we-coagulation.Ngokuqhelekileyo, i-particle diameter incinci kwaye ifana, kwaye umphumo we-coagulation ubi;i-particle concentration emanzini iphantsi, kwaye amathuba okuba i-particle collision incinci, engafanelekanga ukudibanisa;xa i-turbidity inkulu, ukwenzela ukuphazamisa i-colloid emanzini, ukusetyenziswa kweekhemikhali ezifunekayo kuya kwanda kakhulu.Xa umthamo omkhulu wezinto eziphilayo zikhona emanzini, unokubhengezwa ngamasuntswana odongwe, ngaloo ndlela utshintshe iimpawu zomphezulu we-colloidal yasekuqaleni, okwenza ukuba iinqununu ze-colloidal zizinzile, eziza kuchaphazela kakhulu umphumo we-coagulation.Ngeli xesha, i-oxidant kufuneka yongezwe emanzini ukutshabalalisa umphumo wezinto eziphilayo , ukuphucula umphumo we-coagulation.

Iityuwa ezinyibilikisiweyo emanzini zinokuchaphazela umphumo we-coagulation.Ngokomzekelo, xa inani elikhulu le-calcium kunye ne-magnesium ion likhona kumanzi endalo, lilungele ukudibanisa, ngelixa inani elikhulu le-Cl- alihambisani ne-coagulation.Ngexesha lezikhukhula, amanzi akhukulisekileyo aphezulu aqulathe isixa esikhulu se-humus angena kwisityalo ngenxa yokukhukuliswa kwamanzi emvula, kunye nedosi yangaphambi kwe-chlorination kunye ne-coagulant esetyenziswa ngokubanzi isekelwe koku.

4. Impembelelo yeemeko zangaphandle zolondolozo lwamanzi

Iimeko ezisisiseko zokudityaniswa kweengqungquthela ze-colloidal kukuphazamisa i-colloidal particles, kunye nokwenza i-colloidal particles edibeneyo idibene.Umsebenzi oyintloko we-coagulant kukuphazamisa i-colloidal particles, kunye ne-hydraulic agitation yangaphandle kukuqinisekisa ukuba i-colloidal particles inokuqhagamshelana ngokupheleleyo ne-coagulant, ukwenzela ukuba i-colloidal particles idibanise omnye komnye ukuze yenze i-flocs.

Ukuze wenze iinqununu ze-colloidal zidibanise ngokupheleleyo kunye ne-coagulant, i-coagulant kufuneka ihlakazwe ngokukhawuleza kwaye ifaniswe ngokufanayo kuzo zonke iindawo zomzimba wamanzi emva kokuba i-coagulant ifakwe emanzini, eyaziwa ngokuba ngumxube okhawulezayo, ofunekayo ngaphakathi kwe-10 ukuya kwi-30. imizuzwana kwaye akukho ngaphezu kwemizuzu emi-2 kakhulu.

5. Impembelelo yomthwalo wempembelelo yamanzi

Ukothuka kwamanzi kubhekiselele kumothuko wamanzi ngamaxesha athile okanye angengawo amaxesha athile wamanzi akrwada, athi atshintshe kakhulu ngesiquphe.Ukusetyenziswa kwamanzi ezidolophini kwimizila yamanzi kunye nokulungelelaniswa komthamo wamanzi anyukayo kuya kuchaphazela amanzi angena kwisityalo, ngakumbi kwinqanaba lokubonelela ngamanzi ehlotyeni, okwenza amanzi angena kwisityalo atshintshe kakhulu, okukhokelela ekuhlengahlengisweni rhoqo kwedosi. yeekhemikhali.Kwaye umphumo wamanzi emva kokutshona awufanelekanga kakhulu.Kuyafaneleka ukuba uqaphele ukuba olu tshintsho alunyuki ngokulandelelana.Emva koko, nikela ingqalelo ukujonga i-alum kwi-tank yokusabela, ukuze ungabhubhisi umphumo we-coagulation ngenxa yomthamo ogqithiseleyo.

6. I-Flocculantamanyathelo okonga

Ukongeza kwezi zinto zingasentla, kukwakho nemilinganiselo yogcino lwechiza, njengokwandisa amaxesha okushukuma kwidama elingamanzi, ukunciphisa imvula yamasuntswana aqinileyo echiza, ukuzinzisa ichiza, nokugcina ukusetyenziswa kwechiza.

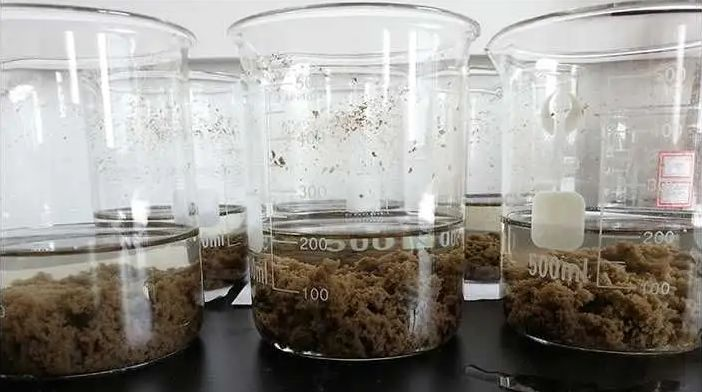

Ukuba i-polyacrylamide ifuna ukugcina iindleko ezisetyenziswayo, kuyimfuneko ukukhetha imodeli efanelekileyo.Umgaqo kukukhetha i-polyacrylamide enesiphumo esihle sonyango, eyona ibiza kakhulu ayiyomfuneko, kwaye ungazami ukuba nexabiso eliphantsi ukuze ubangele isiphumo esibi sokucocwa kwamanzi amdaka, kodwa nyusa ixabiso.Khetha i-arhente enganciphisi kuphela umswakama we-sludge, kodwa iyancipha i-dosage ye-arhente yeyunithi.Yenza iimfuniselo zeflocculation kwiisampulu ezibonelelweyo zoxubo mayeza, khetha ezimbini okanye ezintathu iintlobo zamayeza aneziphumo zovavanyo ezilungileyo, emva koko wenze imifuniselo yomatshini ngokulandelelanayo ukujonga isiphumo sodaka sokugqibela kwaye umisele uhlobo lokugqibela loxubo mayeza.

I-Polyacrylamide ngamasuntswana aqinileyo ngokubanzi.Kufuneka ilungiswe kwisisombululo samanzi kunye ne-solubility ethile.Ukugxininiswa ngokuqhelekileyo phakathi kwe-0.1% kunye ne-0.3%.Ukugxila kakhulu okanye kubhityile kakhulu kuya kuchaphazela umphumo, ukuchitha ichiza, ukonyusa iindleko, kunye nokunyibilikisa i-polymerization yegranular.Amanzi ento leyo kufuneka acoceke (njengamanzi ompompo), hayi ugutyulo.Amanzi kwiqondo lobushushu begumbi anele, ngokuqhelekileyo akukho ukufudumeza okufunekayo.Xa ubushushu bamanzi bungaphantsi kwe-5 ° C, ukuchithwa kucotha kakhulu, kwaye isantya sokutshatyalaliswa sikhawuleza xa ubushushu bamanzi bunyuka.Kodwa ngaphezulu kwe-40 ℃ kuya kukhawulezisa ukuthotywa kwepolymer kwaye kuchaphazele umphumo wokusetyenziswa.Ngokuqhelekileyo, amanzi ompompo afanelekile ukulungiselela izisombululo zepolymer.I-asidi eyomeleleyo, i-alkali eyomeleleyo, amanzi anetyuwa ephezulu ayifanelekanga ukulungiselela.

Nika ingqalelo kwixesha lokunyanga ekulungiseleleni i-agent, ukwenzela ukuba i-agent inokuchithwa ngokupheleleyo emanzini kwaye ingaxutywanga, ngaphandle koko ayiyi kubangela inkunkuma, kodwa ichaphazela umphumo wokuvelisa udaka.Ilaphu lokuhluza kunye nemibhobho zikwathanda ukuvaleka, okukhokelela kwinkunkuma ephindaphindiweyo.Emva kokuba iqulunqwe kwisisombululo, ixesha lokugcina lilinganiselwe.Ngokuqhelekileyo, xa i-concentration yesisombululo i-0.1%, isisombululo se-polymer engeyona i-anionic akufanele sidlule iveki enye, kwaye isisombululo se-polymer ye-cationic akufanele sidlule usuku olunye.

Emva kokulungiswa kwe-arhente, ngexesha lenkqubo yokuxilisa, nikela ingqalelo ekutshintsheni umgangatho wodaka kunye nomphumo wodaka, kwaye ulungelelanise i-dosage ye-arhente ngexesha lokufezekisa umlinganiselo ongcono we-dosing.

Iyeza kufuneka ligcinwe kwindawo eyomileyo, kwaye ingxowa yeyeza kufuneka ivalwe.Ekusetyenzisweni, sebenzisa kangangoko kunokwenzeka, kwaye utywine iyeza elingasetyenziswanga ukuphepha umswakama.Ekulungiseleleni amayeza, kufuneka kuthathelwe ingqalelo ukuba kungacwangciswa kangangoko kunokwenzeka, kwaye i-liquids ebekwe ixesha elide i-hydrolyzed ngokulula kwaye ayikwazi ukusetyenziswa.

Izixhobo eziqhutywa kakuhle, abasebenzi abarhola iingcali, kunye neenkonzo ezingcono emva kokuthengisa;Sikwalusapho olukhulu olumanyeneyo, nabani na ohlala nombutho uxabisa "umanyano, ukuzimisela, ukunyamezelana" kwiQuots forPolyacrylamideI-Flocculamide Anionic Cationic Nonionic Water Treatment Polyacrylamide, Samkela ngokufudumeleyo abahlobo abavela kuzo zonke iinkalo zobomi bemihla ngemihla ukuzingela intsebenziswano kunye nokwakha ingomso eliqaqambileyo neliqaqambileyo."polyelectrolyte"

I-Quots ye-China Chemical kunye ne-Waste Water Treatment, Ngamandla aqiniweyo kunye nekhredithi ethembekileyo ngakumbi, silapha ukuze sikhonze abathengi bethu ngokubonelela ngomgangatho ophezulu kunye nenkonzo, kwaye siyayixabisa ngokunyanisekileyo inkxaso yakho.Siza kuzama ukugcina isidima sethu esikhulu njengoyena mthengisi ubalaseleyo kwihlabathi.Ukuba unayo nayiphi na imibuzo okanye izimvo, kufunekaqhagamshelana nathingokukhululekileyo.

Ixesha lokuposa: Nov-04-2022