Isithambisi

Inkcazo

Isithambisi esisebenzayo kwii-copolymers ze-acrylic ezingenamanzi ze-VOC, ngokuyintloko ukwandisa i-viscosity kwizinga eliphezulu lokucheba, nto leyo ekhokelela kwiimveliso ezine-rheological behavioral efana ne-Newtonian. Isithambisi sisithambisi esiqhelekileyo esinika i-viscosity kwizinga eliphezulu lokucheba xa kuthelekiswa nezithambisi zemveli zamanzi, kwaye inkqubo etyebileyo isebenza kakuhle ekubumbeni, ukupeyinta, ukugubungela umphetho kunye nokusebenza okubonakalayo kuphuculwe. Ayinampembelelo ingako kwi-viscosity ephantsi nephakathi yokucheba. Emva koko, i-viscosity ebonakalayo kunye nokumelana nokuwa kwenkqubo azitshintshi phantse.

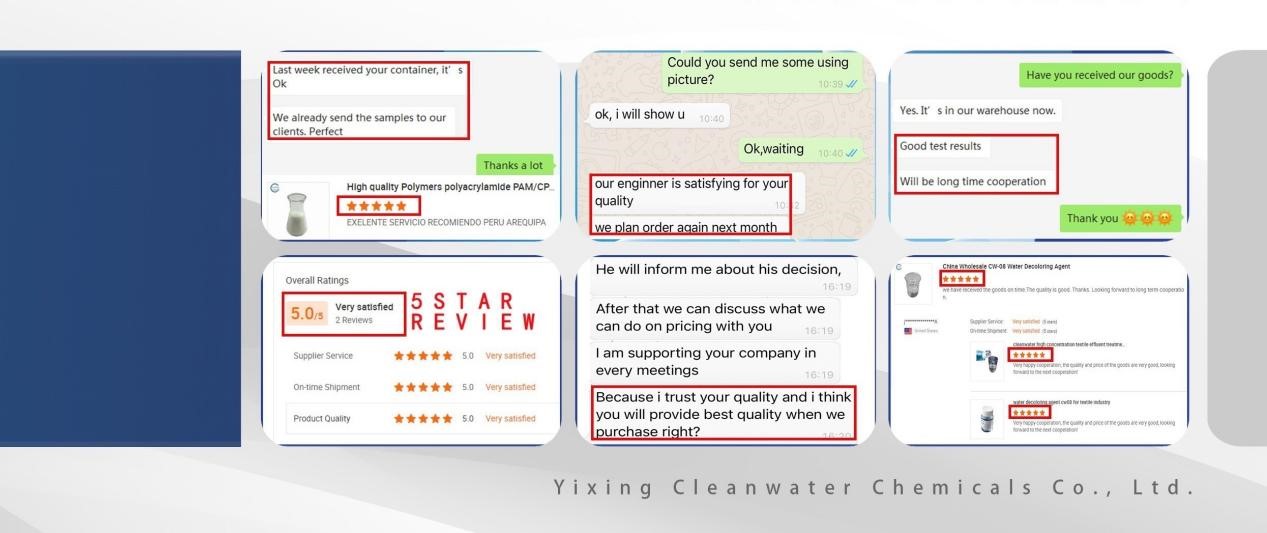

Uhlolo lwabathengi

Iinkcukacha

| INTO | QT-ZCJ-1 |

| Inkangeleko | Ulwelo olumhlophe okwesibhakabhaka oluthambileyo noluthambileyo |

| Umxholo osebenzayo (%) | 77±2 |

| i-pH (1% isisombululo samanzi, i-mpa.s) | 5.0-8.0 |

| Ukuqina (isisombululo samanzi esiyi-2%, ii-mpa.s) | >20000 |

| Uhlobo lwe-ion | i-anionic |

| Ukunyibilika kwamanzi | enyibilikayo |

Intsimi yesicelo

Iingubo zoyilo lwezakhiwo, iingubo zokuprinta, i-silicone defoamer, iingubo zoshishino ezisekelwe emanzini, iingubo zesikhumba, izincamathelisi, iingubo zepeyinti, ulwelo olusebenzayo lwesinyithi, Ezinye iinkqubo zamanzi.

Inzuzo

1. Isithambisi esisebenza kakuhle kakhulu, sihambelana nezinto ezahlukeneyo zokuncamathelisa, kulula ukusilungisa, kwaye sizinzile.

2. Nciphisa iindleko, wonge umbane, unciphise ungcoliseko lokusingqongileyo, kwaye ube nefuthe elicacileyo ekuqinisekiseni ukhuseleko lwemveliso.

3. Isetyenziselwa ukuprinta iirola kunye nokuprinta isikrini esingqukuva nesithe tyaba, nto leyo enokwenza iimveliso eziprintiweyo zibe nomfanekiso ocacileyo, umbala oqaqambileyo kunye nombala ophezulu. Intlama yombala kulula ukuyilungisa, izinzile kakuhle, ayikhuhli umphezulu, kwaye ayixhumi inethi ngexesha lokuprinta.

Indlela yesicelo:

Ingongezwa kwi-slurry erhabaxa. Iziphumo ezilungileyo zingafunyanwa xa ifakwa emva kokufakwa kwinqanaba langaphambi kokupeyinta. Kule meko, kufuneka kuthathwe ingqalelo ukujonga ukuba inkqubo yokugquma iyahambelana na, ngenxa yomphezulu we-polymer particles ophezulu kakhulu. Ke ngoko, inokubangela ukujiya okanye ukuxinana ngenxa yokusebenzisana kakhulu kwendawo. Ukuba le nto yenzeka, kucetyiswa ukuba uyixube namanzi kwangaphambili, njengokuxuba ukuya kuxinzelelo lwe-10% ngaphambi kokusetyenziswa.

Ukwanda kwe-viscosity ephezulu ye-shear kuxhomekeke kubungakanani obongeziweyo, ubungakanani obuchanekileyo buxhomekeke kwi-rheology efunekayo kwi-coating ethile.

Amagqabaza: Kungcono ukongeza isixa esifanelekileyo (0.5%-1%) samanzi e-ammonia kunye noxinzelelo lwe-20%. (Le ngcebiso isekelwe kwiimfuno zemveliso)

Ngokubanzi, i-0.2-3.0% yongezwa kwisixa siphela, kwaye umbala wemveliso umhlophe njengobisi.

Iphakheji kunye noGcino

1. Idrama yeplastiki, 60kg 160 kg

2. Pakisha kwaye ugcine imveliso kwindawo evaliweyo, epholileyo neyomileyo, enomoya opholileyo

3. Ixesha Lokusebenza: Unyaka omnye, Xuba ngaphambi kokusetyenziswa ngakunye ngaphambi kokongeza

4. Uthutho: Iimpahla ezingezizo eziyingozi